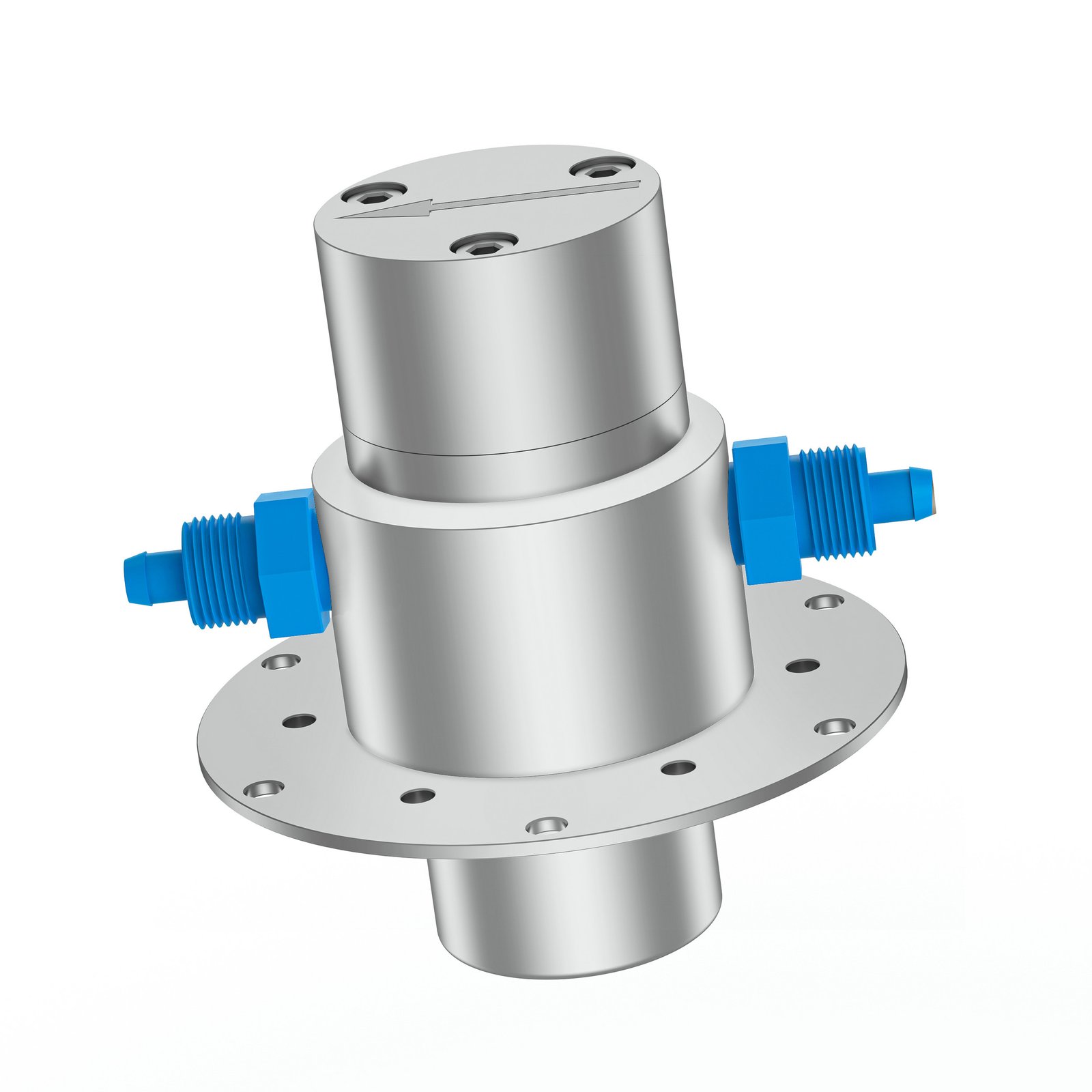

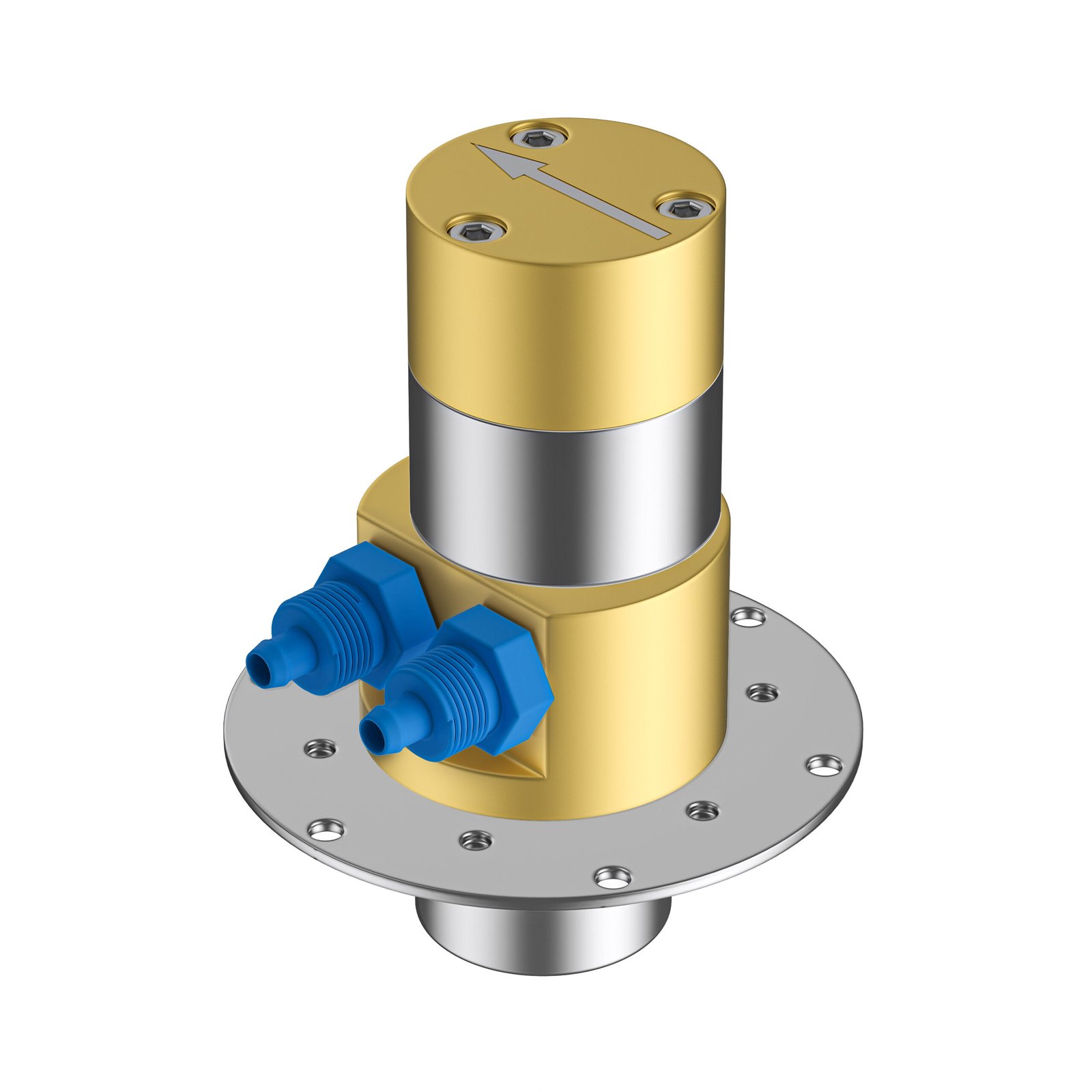

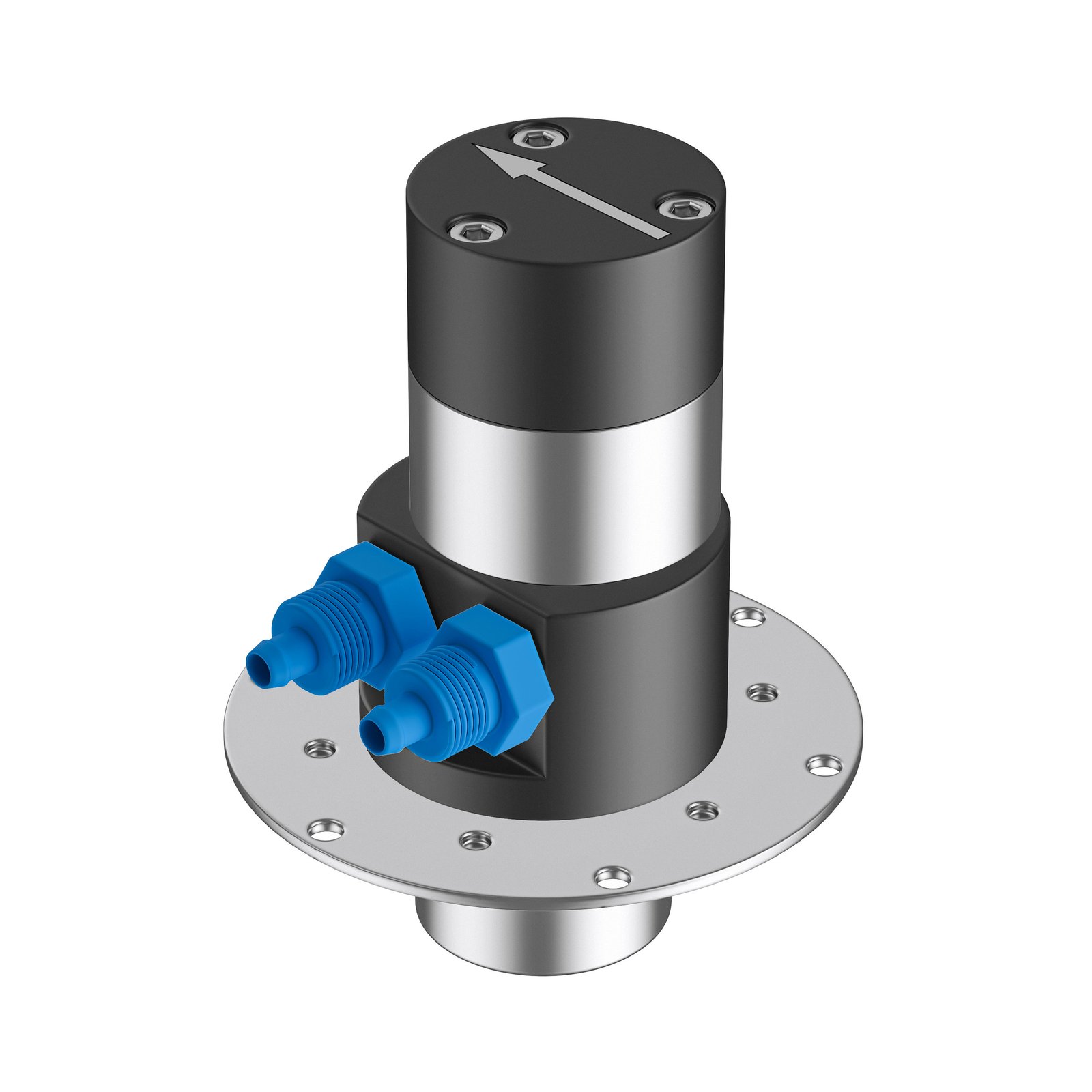

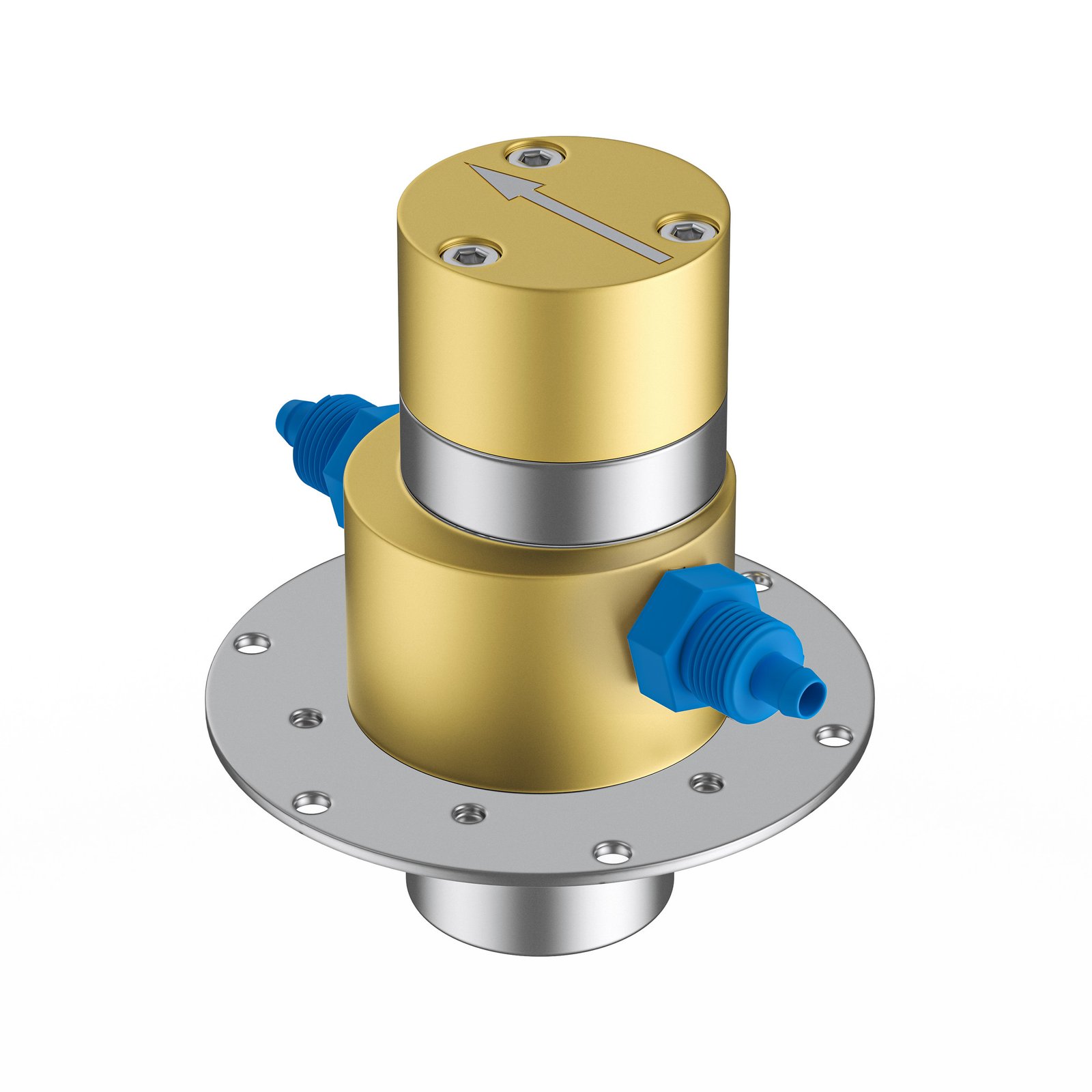

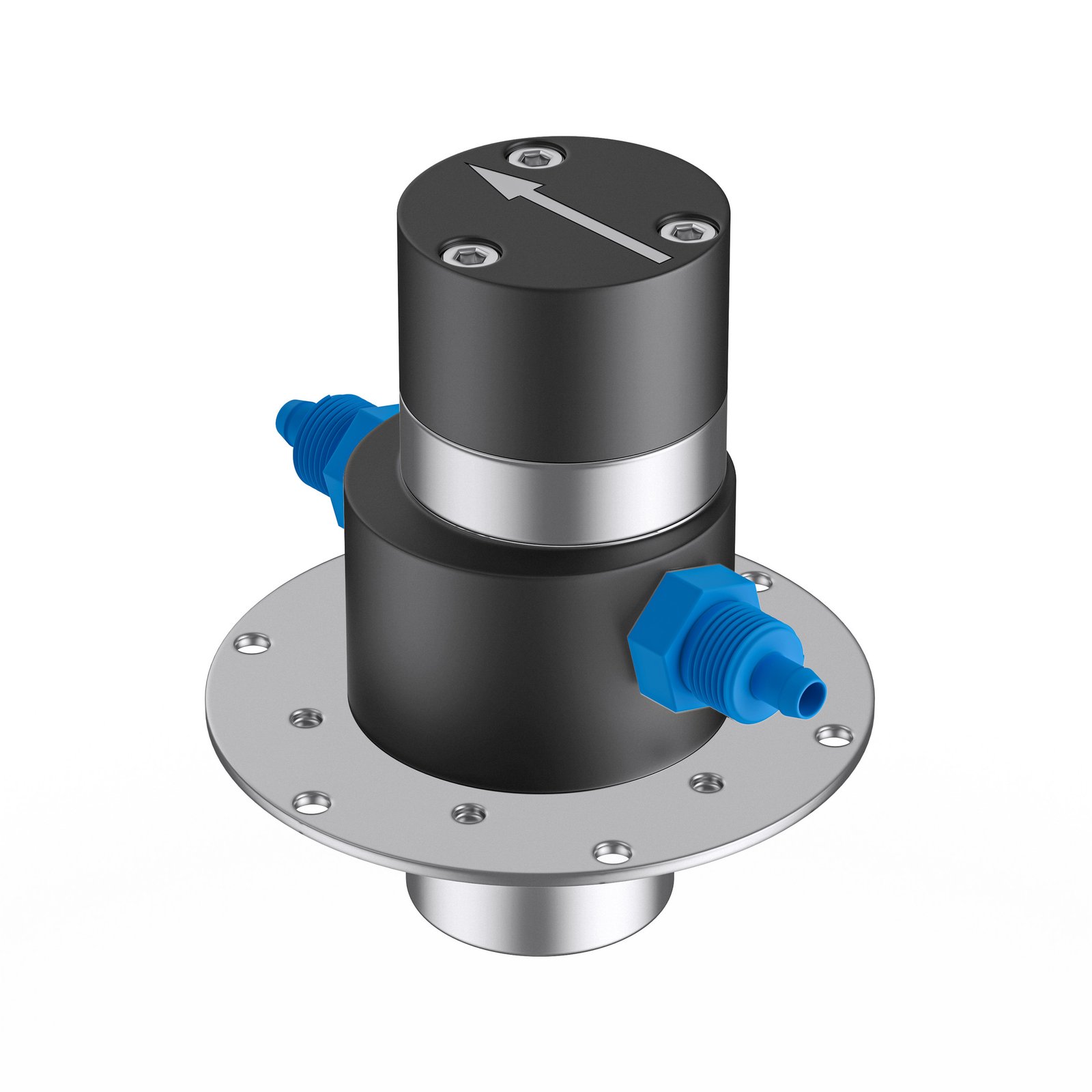

Gear Pump Parts Injection molding

Are You Facing Technical Challenges in Gear Pump Injection Molding?

In gear pump injection molding, precision and sealing are critical factors determining product quality. As industrial standards continue to rise, these challenges become increasingly demanding.

Are You Experiencing These Issues?

- High scrap rates due to micron-level precision requirements

- Sealing problems caused by small contact areas between sealing surfaces and O-rings

- Microscopic structures that traditional injection molding techniques struggle to produce

- Low production efficiency affecting delivery times

Technological Innovation: Pushing the Boundaries of Precision Injection Molding

Conventional methods often fall short when dealing with 1mm surface sealing requirements. However, through continuous technological innovation and experience accumulation, breakthrough solutions have emerged.

Product Performance and Processes

Our gear pump injection molding products utilize advanced processes and high-quality materials to ensure exceptional performance and durability. Here are the detailed specifications of our products:

Core Advantages of Our Innovative Solutions:

- Mold designs optimized for microscopic structures

- Innovative injection molding processes ensuring sealing surface integrity

- Quality inspection under 50x magnification

- Rigorous sealing performance testing procedures

| Parameter | Specification | Notes |

|---|---|---|

| Plastic Material | PPS, PPS+40%GF, PA66+30%GF | Selected based on application scenario |

| Temperature Range | -40°C to 150°C (-40°F to 302°F) | Suitable for extreme environments |

| Pressure Resistance | ≤30MPa (4,351 PSI) | Maintains stable performance under ultra-high pressure |

| Precision Grade | ±0.005mm (±0.0002 inches) | Industry-leading level |

| Sealing Performance | Leakage rate < 0.1 mL/min @ 20MPa | Exceeds industry standards |

| Service Life | >10,000 hours | Long-term stable operation |

| Noise Level | <65 dB | Low-noise operation |

| Efficiency | >95% | High-efficiency energy conversion |

| Warranty Period | Standard 2 years, extendable to 5 years | Demonstrates confidence in product quality |

Unique Processes:

- Microscopic structure optimization injection technology: Improves product precision by 30%

- Precision temperature control system: Temperature fluctuation controlled within ±0.5°C (±0.9°F)

- High-precision mold design: Mold life increased by 50%, ensuring long-term stable production

- Advanced post-processing technology: Surface roughness can reach Ra 0.2μm

Quality Certifications

Our products and production processes have obtained multiple international certifications, demonstrating our unwavering pursuit of quality:

- ISO 9001:2015 Quality Management System Certification

- ISO 14001:2015 Environmental Management System Certification

- IATF 16949:2016 Automotive Industry Quality Management System Certification

- CE Certification: Compliant with EU safety, health, environmental protection, and consumer protection requirements

- UL Certification: Meeting North American safety standards

- RoHS Compliance: Ensuring products are free from hazardous substances

Creating the Future Together

On the path of precision manufacturing, we sincerely invite you to join us. Each of your requirements drives our technological innovation. We look forward to in-depth discussions with you on how to apply these advanced technologies to your production, injecting new vitality into your products.

You might be considering:

- How can these innovative technologies be integrated into existing production lines?

- What benefits can the adoption of new processes bring to your business?

- What challenges might be encountered during the technological transition?

Let’s sit down together and discuss these questions in detail. Every query you have deserves our careful attention. We look forward to the opportunity to show you more, listen to your ideas, and jointly outline the blueprint for future precision manufacturing.

Professional Consultation

- Factory Address: 101, Building 1, Jiumo Tech, Shajing, Bao'an District, SZ, CN

- +86-0755-27691164

- +86 13632611848

- info@gbmmould.com

If you’re interested, we can arrange a no-pressure technical exchange meeting. Here, we can delve into your specific needs and tailor the most suitable solution for you.

Please fill out the form below, and we’ll arrange for our technical experts to have an in-depth discussion with you to explore the solution that best fits your needs.